Parametric design: find out the works by Devoto Design

Parametric design: what are its advantages and what is it possible to do today thanks to the process of algorithmic modelling? In this short article, we’ll try to explain what parametric design is through some of the works we have delivered in the past years..

The majestic canyon of light and wood at the National Museum of Qatar Gift Shops; big “Nuvola” in Rome; the archive room desk at the MAXXI museum in Rome; Vertigo Restaurant on the 28th floor of the luxury Banyan Tree Doha hotel. If you are wondering what these projects have in common, the answer is: parametric design.

Parametric design and algorithmic modelling: what are they?

By “parametric design” we mean the work techniques based on the decomposition of complex surfaces into construable elements obtained through a system of construction algorithmic modelling. The modelling makes possible the fabrication of all the elements that will form the project surface.

Thanks to this particular design technique it is possible to conceive and deliver projects with complex surfaces and to detail the decomposition and composition of its elements – exactly like a big jigsaw puzzle – but also to reduce the margin of error to zero.

This kind of design is “parametric” because it provides as output a series of rules in form of “parameters” that, once inserted in specific design software, originate forms that can be furtherly modelled.

Curious fact: the terms “algorithmic” and “parametric” in this specific context can be used as synonyms. Both refer to “the fact that the parametric modelling software uses mathematic algorithms to describe the processes and activities that are translated into tridimensional models” (source: fablabvenezia.org).

Thanks to the union of creative and computing processes, today it is possible to conceive extremely innovative and original design solutions.

Besides, thanks to the contribution of parametric techniques, it is possible – as it is easy to guess – to analyze different project options and at the same time to grant an incredibly advanced level of customization, as it is possible to see in the pictures of the works we delivered.

One of the creative challenges the parametric design proposes is the possibility to imitate and reproduce the complex and beautiful shapes of nature with a level of accuracy that was not conceivable before.

It’s as astonishing as passing from the vision of a black and white movie on a screen to the presence of a hologram in the room..

Parametric design: some works by Devoto Design

Here are some of the works delivered by Devoto Design in the past years where parametric design was employed.

By clicking the following links it is possible to learn more about the genesis and details of the single projects.

Rome Convention Centre “Nuvola”

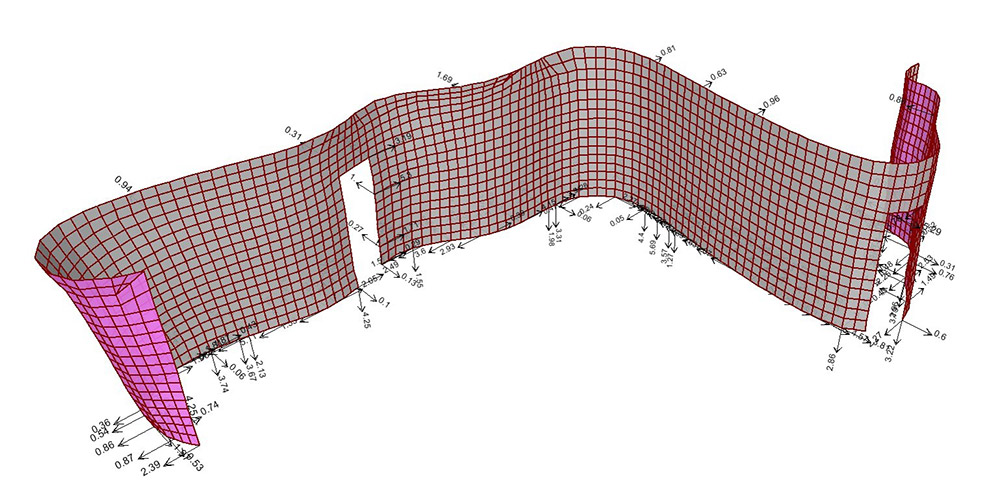

This project involves the partition of both the internal and external surfaces of the auditorium into panels. More than 7.000 panels have been designed and installed in the auditorium.

To do this we have created a specific design software that could calculate the exact number of panels per typology. For instance, the number of straight panels, the double-curving ones, the single-curving ones, and those with a fold on the diagonal.

DEVOTO DESIGN “supplied and installed more than 4000 double-curving panels” and “also took care of the parametric development of the project as well as of the analyisis and design of the metal substructure that holds the wood cladding”.

MAXXI – National Museum of XXI century arts

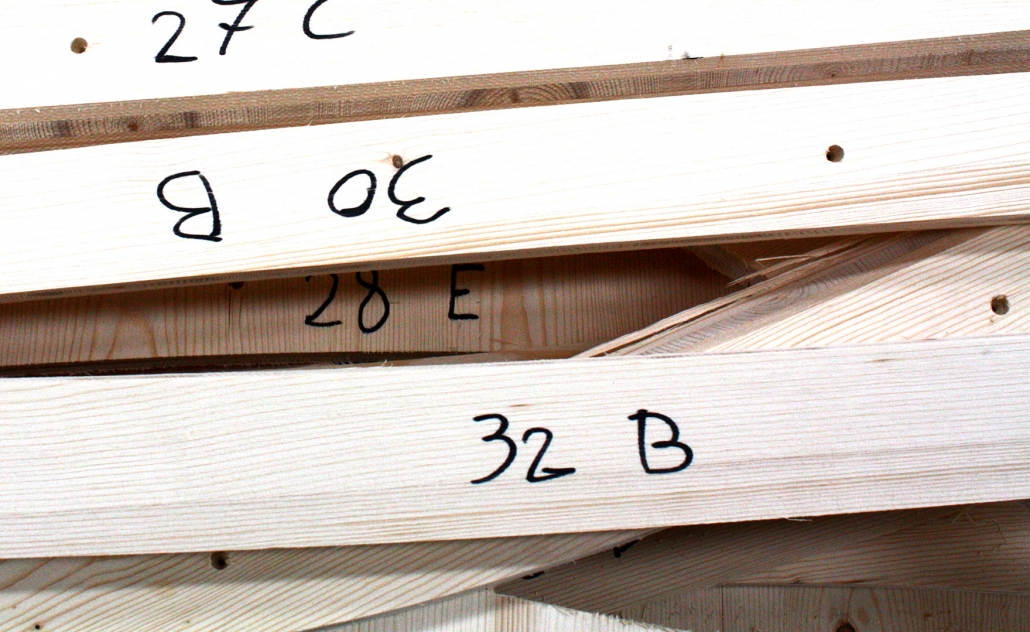

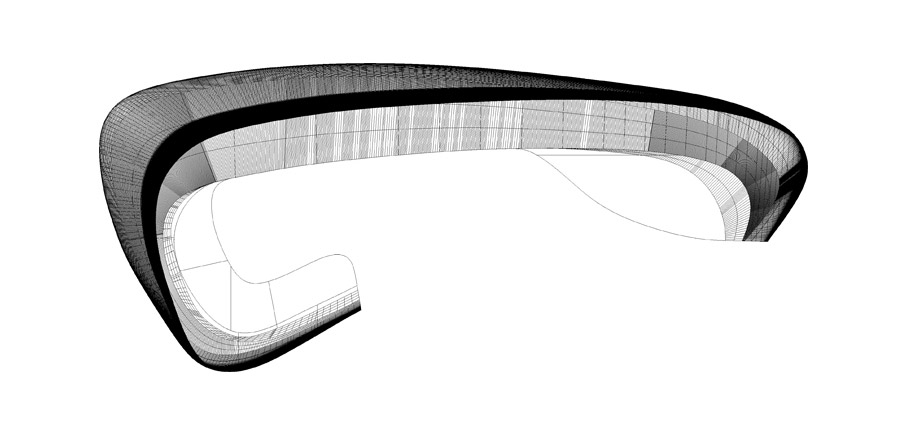

For the MAXXI Museum Devoto Design delivered several items: reception desks, wardrobes, the cafeteria, the lavatories, and the archive room desk. “Among all, the archive room desk is undoubtfully the most complex one because of its great dimensions and its plastic-like surface and variable sections”. In this case, parametric design has helped divide the imposing organic shape of the desk into horizontal wood elements. Once assembled the wood pieces formed the three sections the desk had previously been divided into.

The MAXXI museum desk “divided into three sections for transport and construction feasibility reasons, is made of about 1600 pieces of wood organized in horizonatle layers. Every piece, different from the others for dimension and shape, had its own specific CAD-CAM program. The nesting established the process schemes for the CNC cut.

MAXXI The National Museum of XXI Century Arts

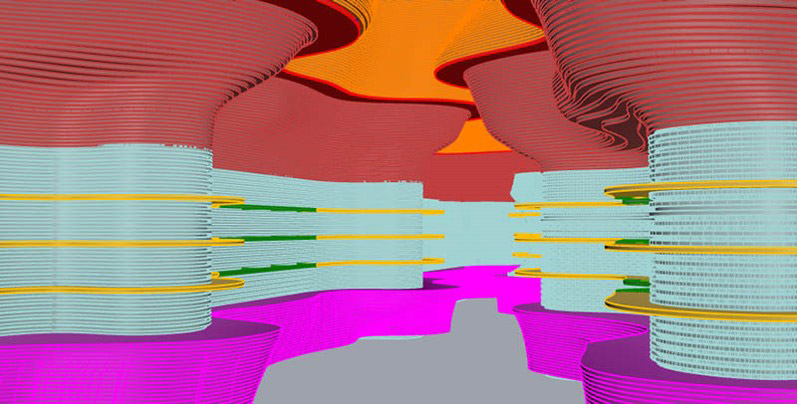

National Museum of Qatar Gift shops and Vertigo Restaurant

For the Gift Shops and the walls of the Banyan Tree Doha Vertigo Restaurant, we have employed the same design approach. We cut the surface into wood pieces like in a big jigsaw puzzle.

To obtain the pieces we used – in this case too – a customized software we adapted to the specific project needs.

“To get the double-curving shape of the walls we used more than 22.000 wood pieces…” (Devoto Design about Vertigo Restaurant)

You can read the whole story of the complexity of these projects and the related design solutions we found in the dedicated articles.

“We were satisfied with Devoto Design’s methodology of engineering how to put together the three-dimensional jigsaw puzzles of 40,000 pieces of wooden panel. ” (Koichi Takada Architects su Gift Shop Qatar National Museum)

Qatar Museum Gift Shops Construction: find out how we made it possible!

Double Curvature, a special project for the Banyan Tree Doha Vertigo Restaurant

To learn more:

- Parametric Architecture: visit one of the International reference websites about parametric design

- “Parametric design and algorithmic design” in FabLabVenezia.org, where the quote in this article comes from.

devoto design

devoto design

devoto design

devoto design

devoto design

devoto design

Leave a Reply

Want to join the discussion?Feel free to contribute!