Location | Roma

Date | 2010

Client | Fondazione MAXXI

Design | Zaha Hadid Architects

Engineering and manufacturing of complex surfaces

When we talk about complex and double-curved surfaces, customized finishes and structures, we can help our clients find the right construction solution thanks to our experience in the delivery of strongly-customized works.

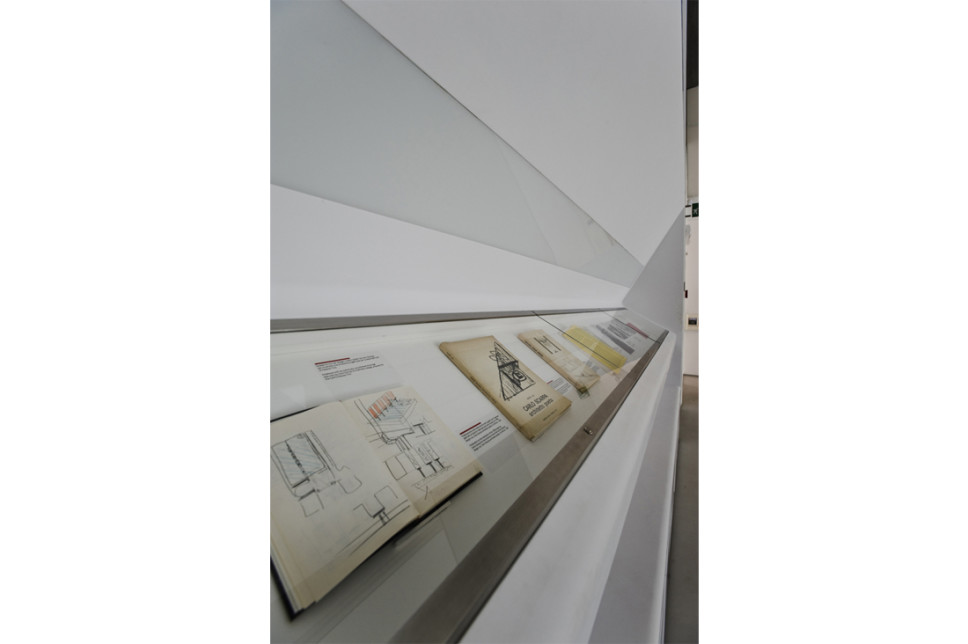

Devoto realized different pieces and complements for the interiors of the MAXXI museum: desks, containers for the cloak room, the caféteria, the bathroom furniture, the 5-metres-tall lift furniture and the desk for the Archive Room. Among all of them, the Archive desk is definitely the most complex one, as for its remarkable size and its plastic surface with variable sections. The project idea fully and clearly explains its complexity: a volume of great dimensions, double curves, a milk-white skin and a continuous surface, consultation areas and containing elements to be placed on Level 0 of the museum.

Devoto cured all the phases of the process:

STEP 1 – Requirements analysis. A multidisciplinary team welcomed the project by Zaha Hadid, ran the technical and economical feasibility study, analyzing solutions and materials with the help of a scale model, to weight the compatibility with the client’s expectations.

Devoto had to consider the complexity of the project, the production process, the materials to use and the surface finishing, the delivery logistics, the Gantt and the budget. Finally, quality assurance.

STEP 2 – Executive Study. During this phase, Devoto cooperated with the designers. The 3D model was optimized because of the passage from a solid modeling software to the CD-CAM one for the CNC machinery cut. The desk, divided into three parts for transport and production feasibility reasons, was stratified into horizontal sections composed of about 1600 pieces. Every piece, different in size and shape from the other, had its own specific CAD-CAM program. The nesting process established the schemes for the CNC CAM procedure.

STEP 3 – CNC production and assembly. The 5 axes CNC machine and the pieces codification system (programmed during the executive study) allowed the proper preparation of the constitutive elements for the manual assembly phase: every single piece, was not only modeled in its three dimensions but at the same time was pierced to help and make the following assembly process easier.

STEP 4 – surface finishing. The painting team took care of the surface finishing of the assembled parts of the desk. They started by fixing the wooden surfaces in order to delete any imperfection of profile and superficial shaping. After the sanding came the resin, with an alternation of Matt fabric and resin, followed by a layer of white Gelcoat, both sprayed and applied. The final sanding helped get the required Matt surface finishing, checked and approved by the designers.

STEP 5 – delivery. Following the procedure established during the feasibility analysis, the delivery was characterized by the assembly on site of the three parts of the desk. A big unique volume was got, connecting the three parts in an invisible way, thanks to the above-mentioned surface finishing process.

The MAXXI museum project has been a turning point for Devoto for what concerns the research on double-curved geometries. Facing such an innovative and complex architectural style has let Devoto start a research activity to grow its know-how and knowledge in other fields too. At the same time, this project started a process of prototyping actions in order to find possible solutions that had been supposed but needed to be tested, perfected and certified.

Photo credit: Zeno Colantoni

devoto design

devoto design tom ferguson

tom ferguson