Luxury hotel interior fit-out: craftsmanship and technology…

Luxury hotel Interior Fit-out: when craftsmanship, technology, parametric design and materials of different nature perfectly mix up and give birth to a prestigious project…

In one of the most famous neighbourhoods of Rome we can find a luxury hotel designed by the London-based Zaha Hadid Architects. For this project Devoto Design is currently delivering the public areas of the hotel and today we’ll sneak a peek at the Gym and we’ll also try to explain why we like to call it “the kingdom of the cusps”.

Luxury hotel Interior fit-out: the double-curving claddings

The installation works we have started in May are currently going on. In the public areas designed by Zaha Hadid Architects Devoto Design is taking care of the complex installation of the double-curving claddings on both walls and ceilings, strongly characterized by consistent surfaces, curving geometry and organic shapes.

THE DIFFICULTY BEHIND THIS PROJECT: “…was not in its organic shapes (something Devoto can proudly and easily handle – see the Banyan Hotel Vertigo, for instance) but in making the wooden cladding look as harmonious, accurate and consistent as possible. But it was possible thanks to the craftsmanship skills and the insight of our technicians. Once again technology and craftsmanship worked together to grant the best result and success” (Fabrizio, Project Manager)

The wall and ceiling cladding of the Gym: “the kingdom of the cusps”

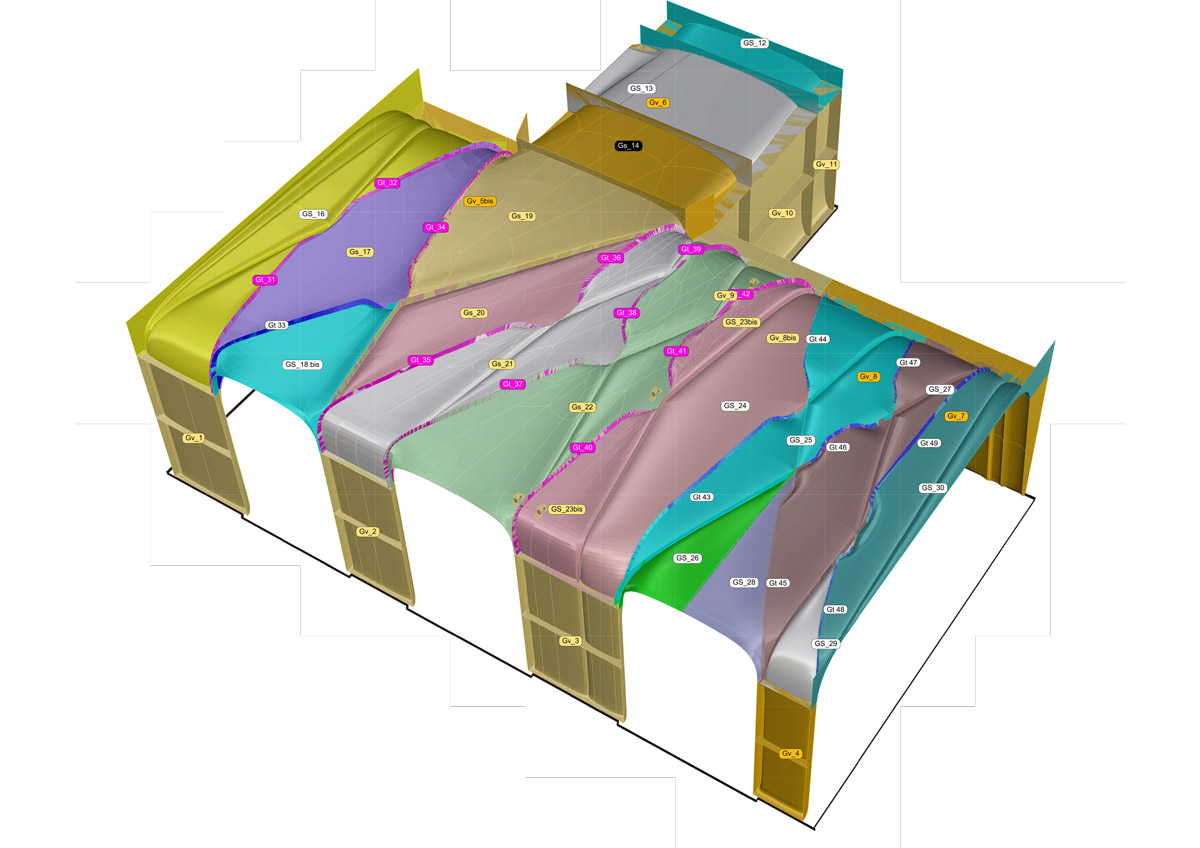

For the Gym of the luxury hotel produced and installed a wall and ceiling cladding. We are talking about a consistent and continuous surface that we parametrized and divided into smaller elements. Each one with its own shape and curve degree. These elements were engineered and produced so that the installation activities could be as smooth as possible and the surface would be as consistent as possible.

FROM 3D TO PRODUCTION: “The gym had looked complex to me since the first glance I had at the 3D model, with shapes that melt into one another and details that in the mathemathic model are not visible at first. Producing these shapes and being able to finally touch and look at them gave us all the chance to appreciate their design better, especially such details as the cusps. For the ones who don’t know, a cusp is the culminationof two semi- tangent geometric elements that form a zero angle. For me the Gym will always be remembered as the kingdom of the cusps!” (Marco, designer)

Luxury hotel fit-out: from engineering to installation

Here in detail the production process of the elements, engineered and produced in our workshop and eventually transported and installed on site:

- MAKING OF MOULDS: first thing we engineered and produced the moulds in resin

- GELCOAT: then the moulds were covered in gelcoat

- VENEER: the moulds were veneered with thermo-treated ash wood

- FINISHING: the veneered elements were finished with fire-retardant paint

Then these big elements were taken to the hotel site and assembled to form the walls and ceiling of the Gym.

A puzzle with different dimensions

Our technicians worked hard to make sure that the veneering operations could be as fast as possible and the junctions as accurate and invisible as possible.

WHAT’S MORE: The engineering and division in sub-elements had to take into consideration the dimensions and characteristics of the veneering sheets. That’s why you won’t find an element longer that 3 metres..

THE PIECES OF THE PUZZLE: “…in the last months we produced pieces of a puzzle. Thanks to the renders and the drawings we knew what the final result would be, but finally being able to look at the completed puzzle is another story, do you know what I mean? Something to be proud of!” (Arcangelo, Site Team Leader)

Leave a Reply

Want to join the discussion?Feel free to contribute!