BESPOKE DOUBLE-CURVING FREESTANDING FURNISHINGS

Bespoke double-curving freestanding furnishings in record time! How is it possible to deliver complex bespoke double-curving furniture and stick to a tight work schedule?

Easy: first of all, thanks to a deep knowledge of materials and production techniques. But also thanks to the application of a flexible work methodology and to our ability to manage any project and any unpredictable variables. All the better if it we add to this a relationship of perfect communion of intent with the client. In this case you get the perfect formula. The result? A remarkable reduction of time and costs.

So today we’ll talk about one of these perfect experiences of cooperation: that with Design 2000 International.

“TOGETHER WITH THE EXCELLENT MASTERY OF THE CONSTRUCTION TECHNIQUES of double-curving furnishings, the sharing and discussion of all project steps between client and supplier proved essential to both parties and led to a fully satisfactory final result in terms of quality and logistics.” (Design 2000 International)

Freestanding custom furnishings

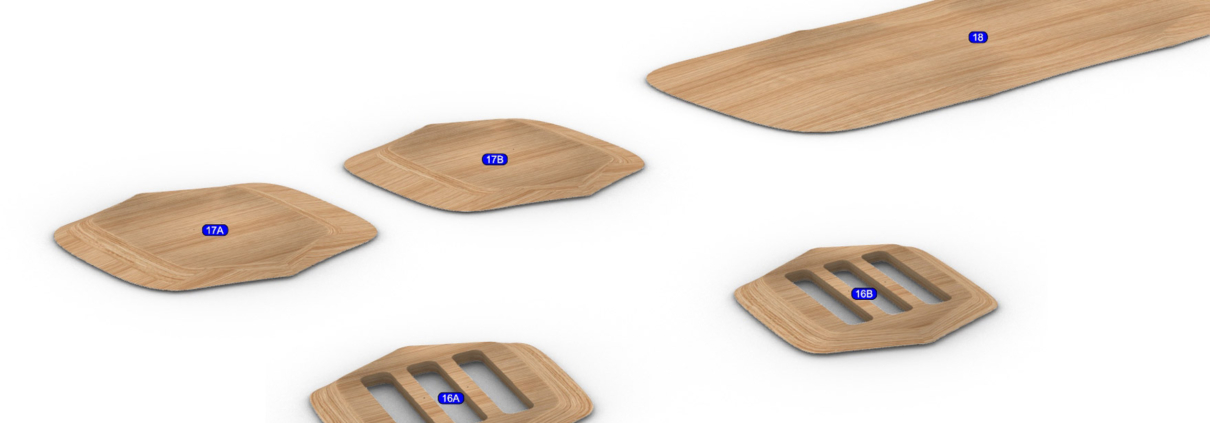

Design 2000 involved us in the technical and economical feasibility study of 18 freestanding pieces of furniture:

- TABLES and coffee tables

- BENCHES in solid oak wood

- CONSOLLES in oak, Botticino marble and rattan

We are talking about layered elements characterized by organic and sinuous shapes.

No particularly critical issues for Devoto Design which knows this type of work well, if not one, which is decisive:

THE SHIP IS ABOUT TO SAIL…

That’s right: delivery times were super tight. Consider that the request for quotation arrived in May and the expected shipment of all the furnishings was the end of August. Nothing to worry about if the procurement of raw materials hadn’t been so uncertain and complicated recently, because of the pandemic first and the war then.

To make things a little bit more complicated in this cooperation with Design 2000 International we had to face some internal variables such as the summer break that always represents a slowdown in supplies due to the closure of supplier companies.

The purchase of raw materials had already been slowed down by the pandemic and was now experiencing other slow-downs because of the international crisis.

These variables, although independent of the processing, were thus managed and integrated into the project planning in order to prevent them from affecting the workflow. We agreed with the customer on a slightly different type of engineering that could speed up the approval times of the technical drawings so as to give precious time to the production phase.

BESPOKE DOUBLE-CURVING FREESTANDING FURNISHINGS: A NEW DESIGN PROCESS

The engineering-production approach was actually the same applied to all the processing of solids in double curvature with an organic shape, by literally “slicing” the items horizontally…

In other words, “construable” sub-elements have been obtained and subsequently assembled so as to obtain the desired shape.

This type of processing requires precise and essential technical construction times. That’s why we have proposed to the customer to intervene on the design process to speed up times and meet the agreed delivery times: we have developed a 3D model of the furnishings and Design 2000 has approved this type of output rather than the usual working drawings… a small exception to the rule for a good cause!

Of course, Design 2000 needed a good deal of trust in Devoto Design…

This could only happen thanks to the excellent mastery of the construction of elements with double curvature as well as an in-depth knowledge of the materials and their characteristics that Design 2000 knows are typical of Devoto Design.

THIS IS THE REASON WHY WE ARE A RELIABLE PARTNER for the construction of custom furniture

AND THE SHIPPING?

All the freestanding custom-made furnishings were then packed and shipped on time. Made of solid wood, all the elements were sent to their destination in refrigerated containers. So as to cope with the sudden changes in temperature and humidity caused by the journey by sea. Destination: Doha.

devoto design

devoto design

devoto design

devoto design  uniexportmanager

uniexportmanager

Leave a Reply

Want to join the discussion?Feel free to contribute!