Location | Brazzaville (République du Congo)

Date | 2011

Client | République du Congo

Design |RC Decò srl

The experience with Oyo was the result of sculptural formal research and a technical and logistic challenge. For RC Decò Studio, Devoto realized five desks with an ellipsoid plan and a double-curved bulged section, completely made of solid wood. They were sent to Oyo, 400 km from Brazzaville. The Client required local essences (Padouk and Zebrawood) – that’s why the raw materials procurement was a pretty complex process. We were able to do that successfully, respecting the company policy that imposes traceability of timber and certification of the source forests.

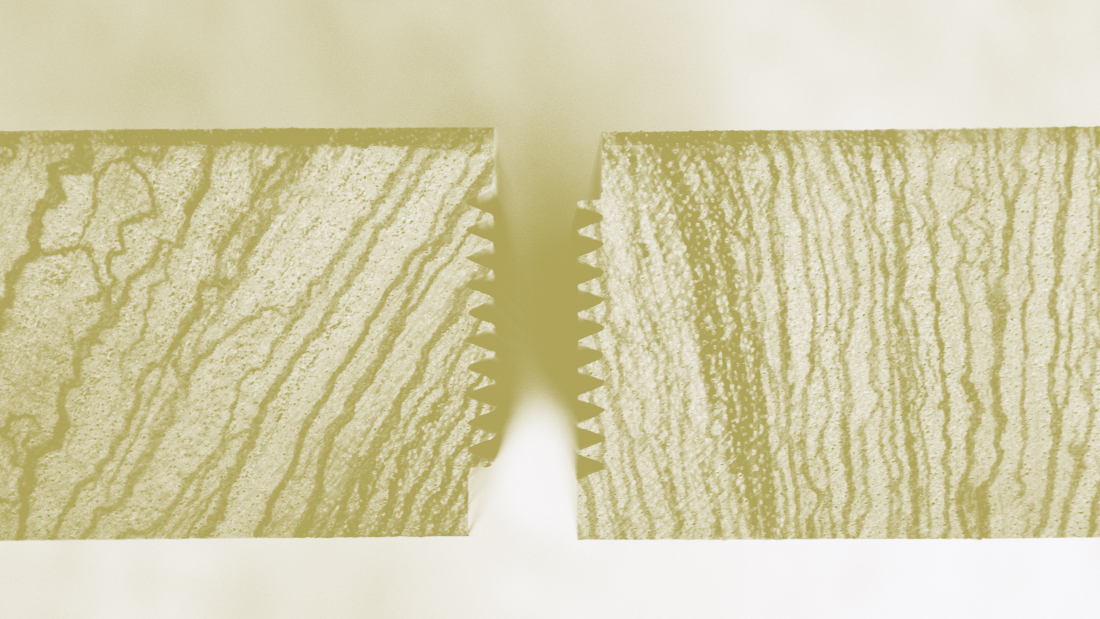

During all the phases of the project definition and production Devoto worked together with RC Decò in a mix of design and production experiences. The realization of the slats that compose the desks was carried out by a CNC procedure, but the management of the finishing was entirely entrusted to traditional methods and to the company know-how in artisanal carpentry.

The desks are made of curved solid wood slats. The boards were previously assembled through a process of nesting, involving both slats and the supports they were cut on. This phase required a quarter of the entire production schedule, especially if you are keen on focusing on the direction of the grain for the cutting and for an aesthetic homogeneity of the assembled slats. The assembly was obtained by the superimposition of the curves, using glue and screws. During the sanding and finishing phase, you really appreciate the previous 5-axes production work, because you can see that the inclination of the sides was perfectly respected. The final finishing looks natural but bright, homogeneous in order to avoid any visual discontinuity. The water-paint coating occurred after a process of stucco works consistent with the wood essence, skimming and sanding.

Devoto offered the services of technical consultancy, production and logistics.

Photo credit: courtesy of René André Comperon

@devotodesign

@devotodesign @maurizio di luzio

@maurizio di luzio